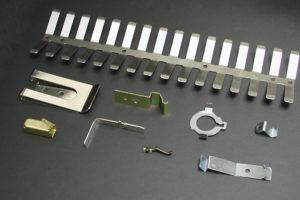

Utilizing cost-effective tooling and the ability to produce short and long runs, we supply high-quality stampings on time, at the lowest possible cost. Our tooling capabilities range from single-stage blank, pierce and forming dies to complex progressive tools depending on the part design and quantities required. First piece, in-process and final inspections are performed to ensure that our customers receive high-quality components part-after-part and run-after-run.

Precision Metal Stamping

At Lansco Manufacturing, we offer a wide range of precision stamping services, including progressive die stamping, deep drawn stamping, and more. Our cost-effective tooling and ability to accommodate both short and long production runs allow us to deliver high-quality stampings on time and with low costs. Here, we will discuss how precision stamping works as well as its different processes, applications, and how Lansco Manufacturing can help you.

Precision stamping is a manufacturing process that converts flat metal sheets into specific, custom shapes. It takes the regular metal stamping process and streamlines it, opting for an automated process to more efficiently produce metal parts. It uses different techniques and tools than the ones used in other less efficient stamping methods.

There are numerous advantages to using precision stamping, such as:

- It is a simple, repeatable process capable of efficiently producing low or high production volumes.

- It lends itself to mechanization and automation, which help increase efficiency.

- The streamlined processes allow for better cost-efficiency in production.

- It’s faster than other manufacturing methods.

Precision Metal Stamping Processes

Lansco Manufacturing offers the following precision stamping processes:

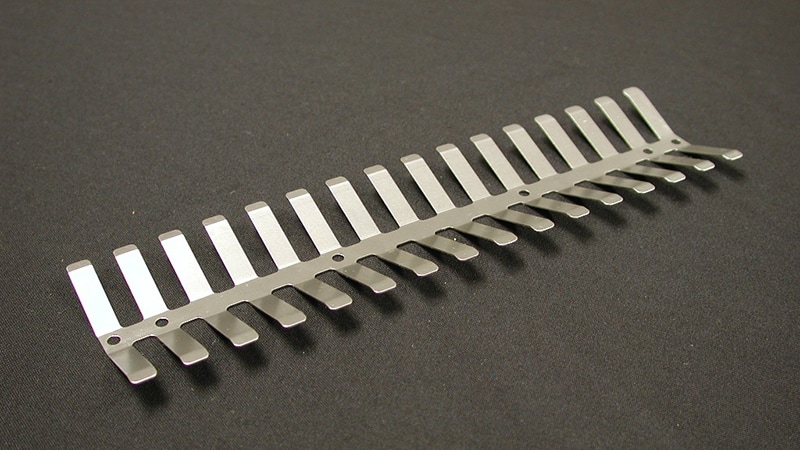

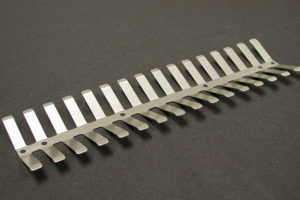

- Progressive die stamping. This metal stamping process employs multiple workstations that each carry out a different function to produce a metal part.

- Compound die stamping. With this method, the compound die performs multiple punches or cuts in one stroke.

- Deep drawn stamping. This process is typically used to make cylinder-shaped metal components by feeding a flat metal coil into a press with multiple tooling stations that carry out repeating operations on the workpiece.

- Piercing stamping. This is a shearing process used to pierce raw metal. This method uses a machining tool to create a circular or other shaped hole in the workpiece.

- Short-run stamping. For short-run stamping, we insert sheet metal between the punch and die. We then use a metal press to shape the metal based on your specifications.

- Single-stage stamping. Using manual dies, single-stage stamping involves carrying out one operation on a part per stroke of the die.

No matter what your specific needs are, we have a precision stamping process that will work for you. We pride ourselves on our ability to work with our customers to come up with the best precision stamping solution for their needs.

Precision Stamping Applications

The precision stamping process is used in a wide range of industries to produce metal parts for various applications. Common industries that utilize this process include aerospace, automotive, electronics, medical device manufacturing, home appliance manufacturing, and telecommunications.

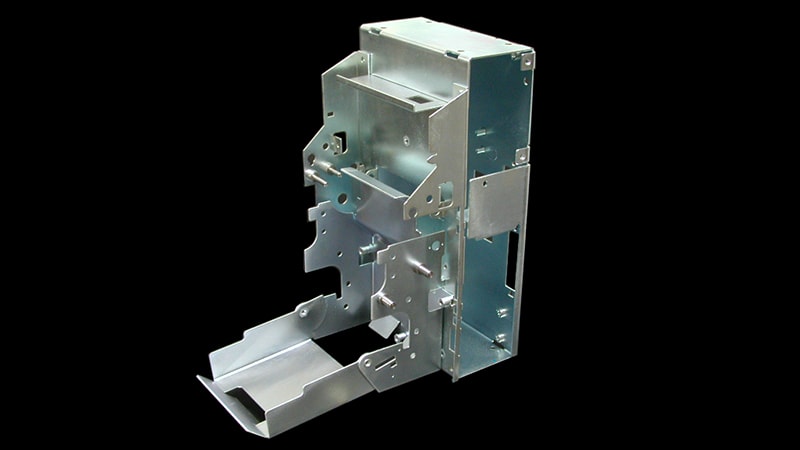

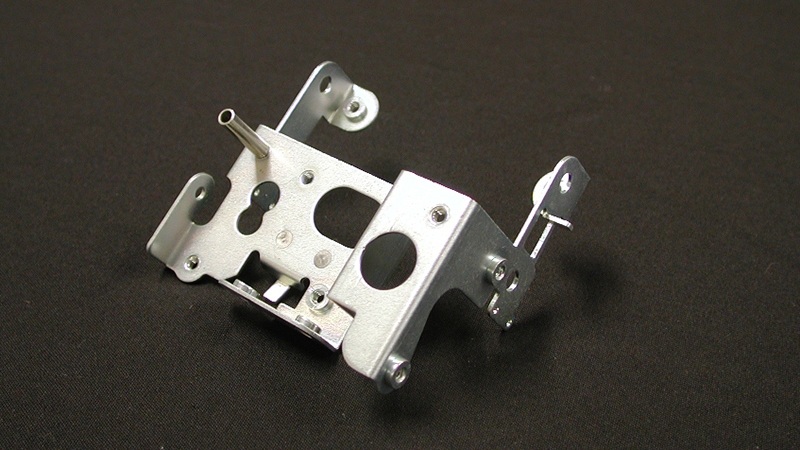

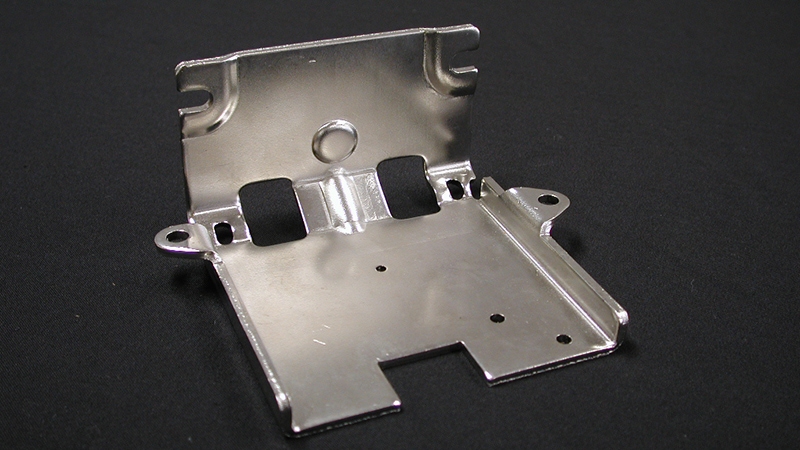

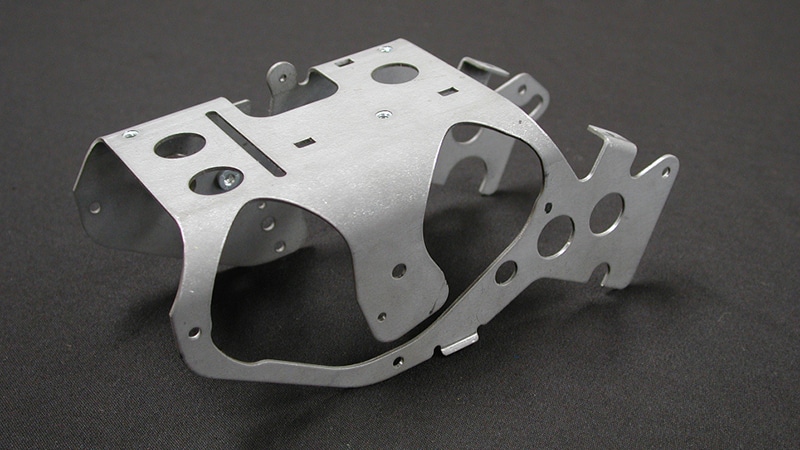

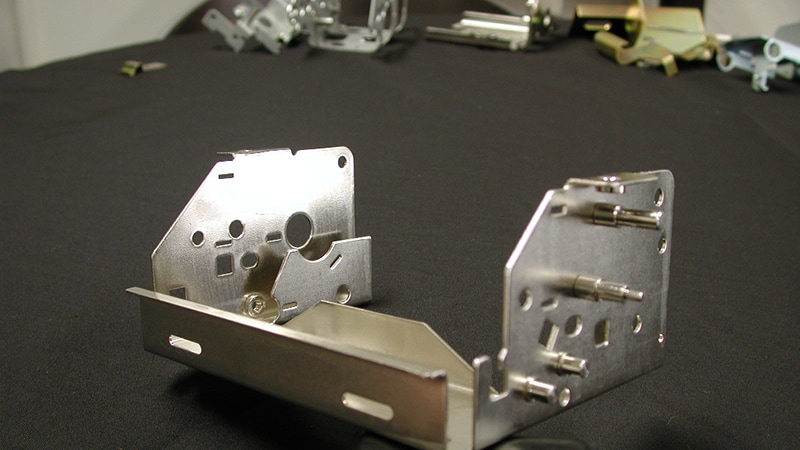

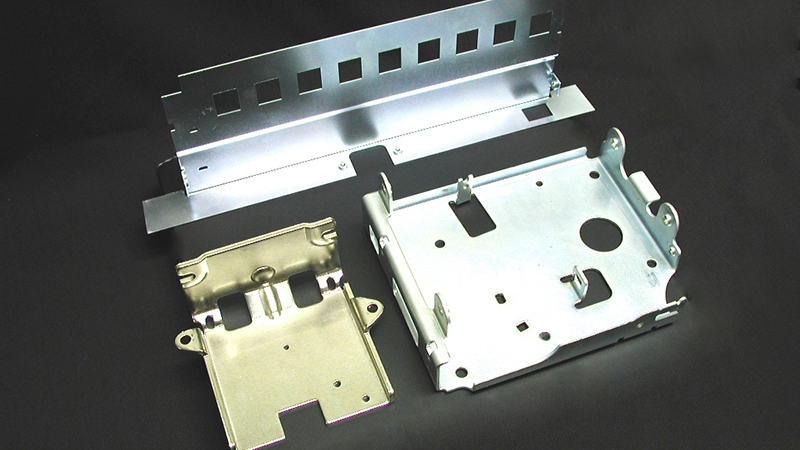

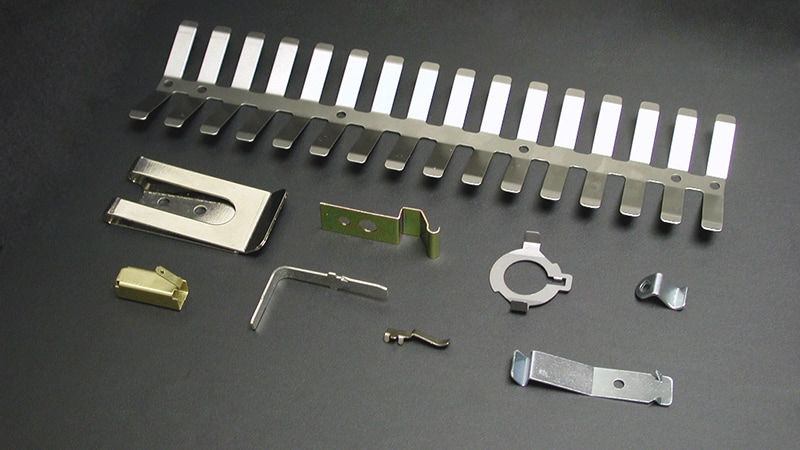

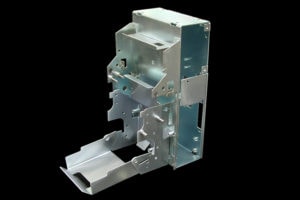

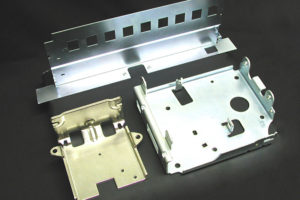

To support these industries, Lansco Manufacturing uses precision stamping to produce a large number of parts, including:

- Brackets

- Chassis

- Covers

- Panels

- Shields

- Washers

Precision Metal Stamping at Lansco Manufacturing

Precision stamping is an efficient, effective process used to create a variety of parts across a wide range of industries. At Lansco Manufacturing, we are experts in precision stamping, and we dedicate ourselves to delivering reliable parts at affordable prices. We perform first piece, in-process, and final inspections to ensure our customers receive the highest quality parts, regardless of design complexity or order quantity. Our precision stamping capabilities and value-added services allow us to provide consistent, accurate components part-after-part and run-after-run.

To learn more about our precision stamping capabilities, contact us today or request a quote to get started on your next project.